Look around any facility, machine, or office door. The unassuming identifiers we rely on every day are often the most overlooked pieces of hardware. Yet, when they are made from stainless steel, they become something more: a permanent, credible, and clean statement.

Stainless name plates are the silent workhorses of identification. They are not just labels; they are enduring assets. This article breaks down why this material is the superior choice for countless applications and what you should consider when ordering your own.

Why Stainless Steel is the Unbeatable Choice

The decision to use stainless steel nameplates isn't arbitrary. It's a practical choice driven by the material's innate properties.

First and foremost, stainless steel is incredibly durable. It resists corrosion, rust, and tarnishing. A stainless steel name plate will look the same years from now as it does the day it’s installed, even when exposed to moisture, chemicals, or outdoor weather.

This leads directly to its low maintenance. Unlike brass or bronze, it doesn’t require regular polishing to maintain its appearance. A simple wipe with a damp cloth is usually all that’s needed. This makes industrial name plates made from stainless steel ideal for environments where cleaning must be quick and effective.

Furthermore, the material offers inherent strength. It resists impact, abrasion, and bending far better than aluminum or plastic. For asset tags on heavy machinery or equipment, this toughness is non-negotiable. Your identification needs to outlast the wear and tear on the asset itself.

Finally, stainless steel carries a universal connotation of quality and professionalism. A metal name plate on an office door or a piece of medical equipment communicates permanence, stability, and attention to detail.

From Design to Delivery: The Creation Process

Understanding how stainless name plates are made helps in planning your project. The journey typically involves a few clear steps.

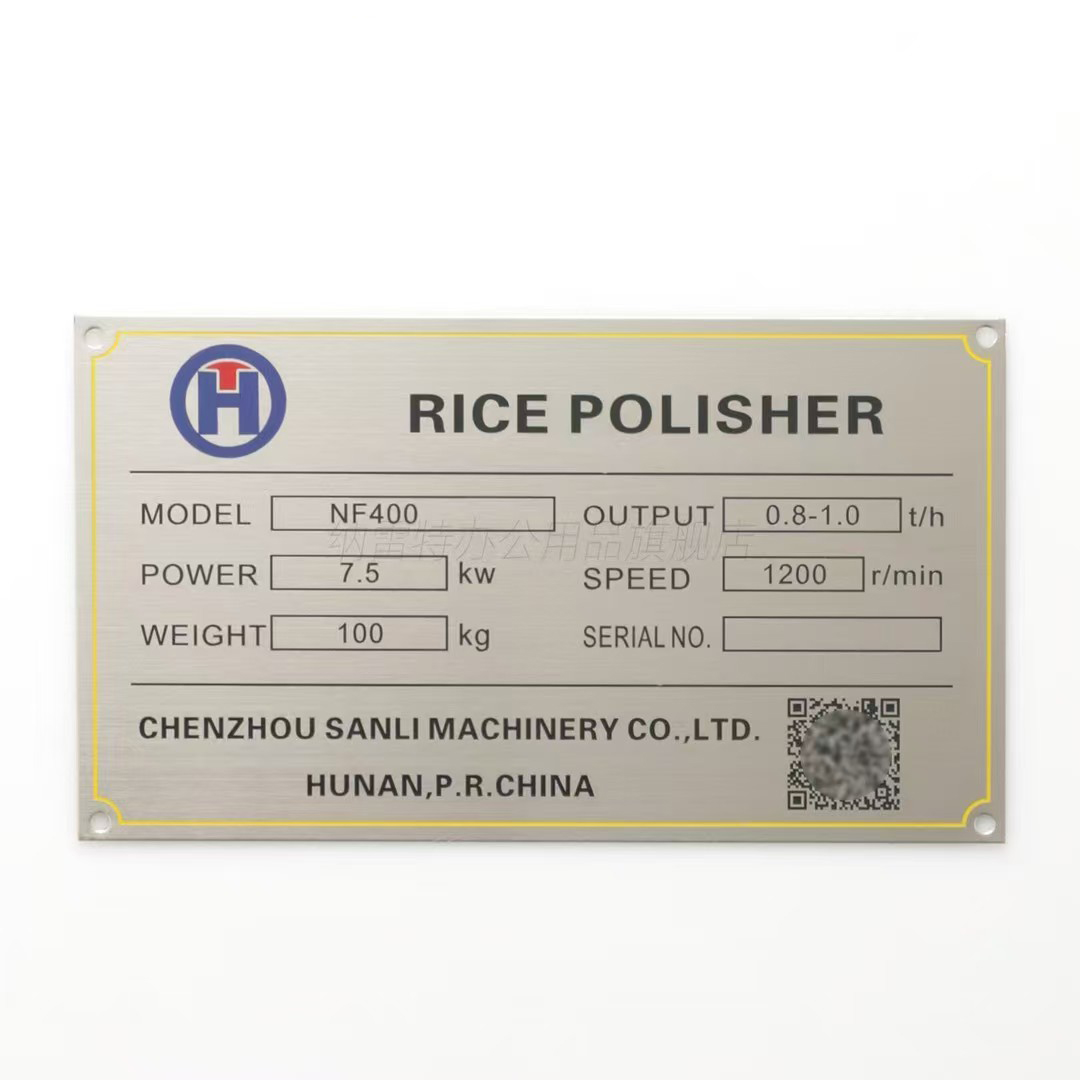

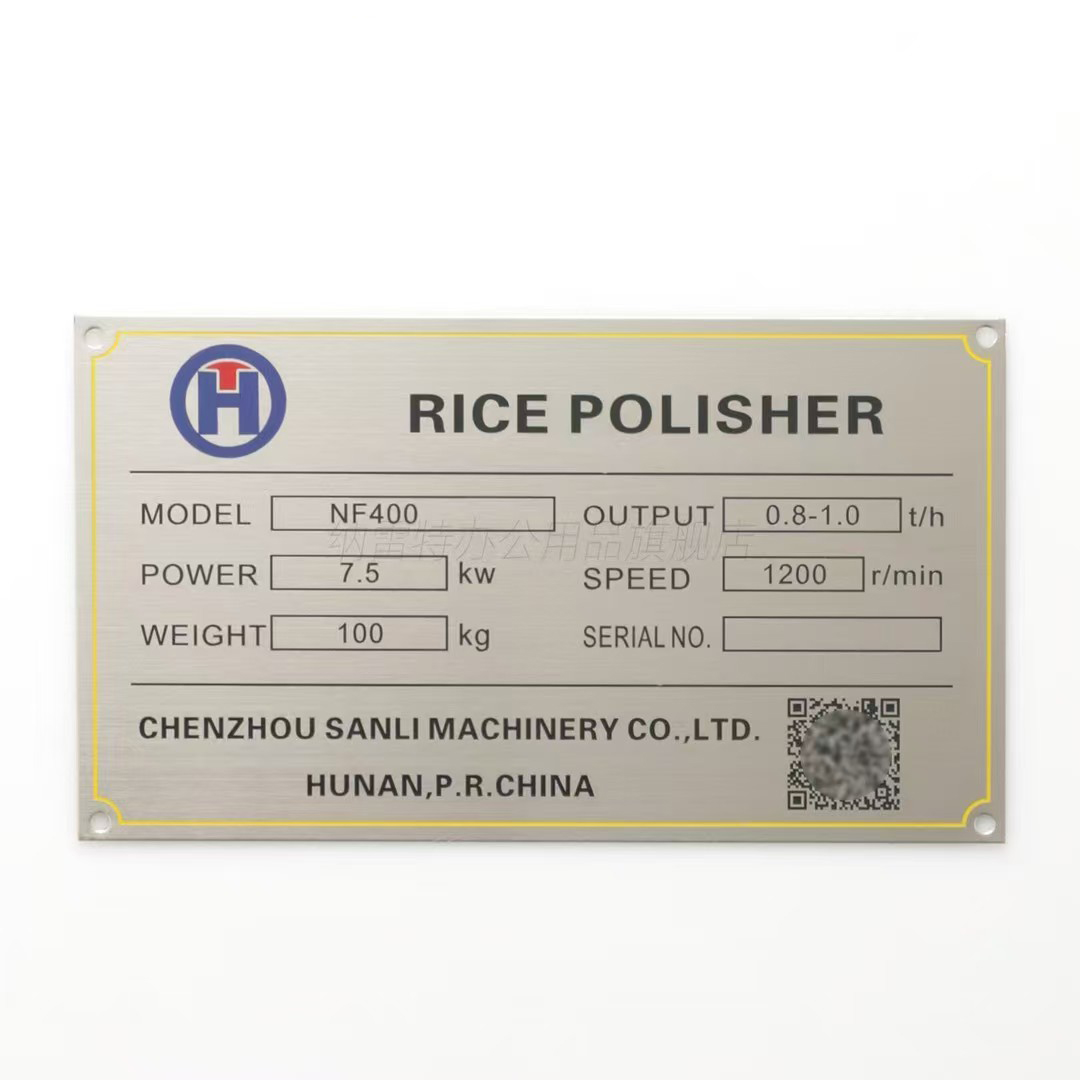

It starts with your design and specifications. What information is essential? Common elements include names, titles, logos, serial numbers, barcodes, QR codes, or compliance markings. Clarity is key, especially for technical nameplates used in manufacturing.

Next, the manufacturing method is chosen based on the need. For most industrial name plates, etching or engraving is preferred. Chemical etching creates precise, shallow grooves that are then often filled with permanent ink (like black or white) for high contrast. Laser engraving vaporizes the material to create marks, excellent for serial numbers and data matrices.

For a more dimensional look, stamping presses the design into the metal. This is common for simpler, high-volume metal tags. Regardless of method, the goal is permanence; the marking should be an integral part of the plate, not just a surface coating.

Finishing touches are then applied. The most common finish is a brushed (satin) or bead-blasted matte surface, which hides fingerprints and minor scratches. A polished mirror finish is also an option for a more decorative stainless steel name plate. The edges are typically deburred for safety and a quality feel.

Where You'll Find Them in Action: Common Applications

The versatility of stainless name plates is remarkable. They solve identification problems across dozens of industries.

In industrial and manufacturing settings, they are indispensable. Used as asset tags, serial plates, and equipment labels, they withstand grease, coolants, and physical abuse. Their readability is critical for maintenance schedules and inventory control.

The medical and laboratory fields rely on them heavily. Here, the easy-to-clean, non-porous surface of a stainless steel identification plate is perfect for sterilization protocols. They are used on autoclaves, surgical tool trays, and permanent facility signage.

Walk into any corporate office, and you’ll see them on doors and desks. Professional office nameplates in stainless steel project a modern, clean, and authoritative image. They lend weight—both literal and figurative—to an executive’s door.

Architects and designers use them for architectural signage in buildings. From room numbers and directional signs to donor walls and memorial plaques, stainless steel offers a sleek, contemporary aesthetic that integrates well with modern materials like glass and concrete.

Key Decisions When Ordering Your Name Plates

To get the best result for your specific need, focus on a few critical specifications.

Material grade is paramount. For most indoor and general-purpose applications, Type 304 stainless steel is the standard. It provides excellent corrosion resistance. For harsh environments—marine settings, coastal areas, or places exposed to salts and chemicals—specify Type 316 marine-grade stainless. It’s more resistant to pitting and corrosion.

Consider the thickness of the plate. Thinner gauges (like 0.5mm) are suitable for flat mounting on surfaces. Thicker plates (1mm and above) are more rigid and substantial, ideal for standalone desk plates or heavy machinery tags where impact resistance is needed.

Think about the attachment method from the start. Will you use industrial adhesive tape on the back? This is clean and popular for flat surfaces. For a more permanent fix, especially on irregular surfaces, through-holes for screws or rivets are the answer. Some stainless name plates come with welded studs on the back for easy mounting.

Finally, prioritize readability. Ensure there is strong contrast between the metal background and the marked information. Black-filled engraving on a brushed stainless background is a classic, highly legible combination for any industrial name plate or office sign.

The Clear Value of a Permanent Solution

In a world of disposable stickers and fading prints, stainless steel name plates stand apart. They represent a one-time investment in clarity, durability, and professional image.

They are not an expense but a long-term asset. They eliminate the recurring cost and labor of replacing worn-out plastic or paper labels. They ensure critical information—from a CEO’s name to a machine’s serial number—remains intact and legible for the life of the product or the tenure of the person.

Choosing stainless steel is a decision for permanence. It’s about making a mark that is meant to last, to endure, and to communicate credibility every single day.

Frequently Asked Questions About Stainless Name Plates

Q1: What’s the real difference between 304 and 316 stainless steel for name plates?

A1: The core difference is corrosion resistance. Type 304 is excellent for most environments and is the standard for indoor office nameplates and general industrial name plates. Type 316 contains molybdenum, which gives it significantly higher resistance to chlorides and acids. It is the necessary choice for coastal areas, marine applications, chemical processing plants, or any setting with exposure to salt or harsh chemicals.

Q2: Can you add color to stainless steel name plates, or are they only silver?

A2: Absolutely. While the natural silver finish is popular, color is commonly added for branding or visibility. The most durable method is through chemical etching or laser engraving and then filling the recessed areas with hard-wearing enamel paint (like black, white, red, or blue). For full-color logos, a durable overlay or sublimation printing process can be used, though etched and filled color tends to be the most resilient for long-term outdoor or industrial use.

Q3: How are stainless name plates typically attached to surfaces?

A3: There are three primary methods. First, high-strength industrial adhesive tape (like 3M VHB) is extremely popular for flat, clean surfaces like doors, glass, or smooth machinery. It provides a clean look with no holes. Second, through-holes allow the plate to be fastened with screws or rivets, offering the most permanent and secure mounting. Third, some plates can be ordered with welded studs on the back, which are then inserted into pre-drilled holes and secured with nuts.

Q4: Are custom shapes possible, or are they limited to rectangles?

A4: Custom shapes are absolutely possible and are a great way to enhance brand recognition. While rectangles and ovals are standard for cost-efficiency, modern laser cutting technology allows for the production of stainless steel name plates in virtually any shape—company logos, unique silhouettes, or radii corners. Discussing your design with the manufacturer early in the process is key to understanding any limitations or additional costs.

Q5: What information should I provide to get an accurate quote for custom name plates?

A5: To receive a precise quote, be ready with the following: 1) Quantity, 2) Dimensions (length, width, and thickness), 3) Material Grade (304 or 316), 4) Finish (brushed, polished, etc.), 5) Marking Method (etching, engraving, stamping), 6) Color Requirements, 7) Attachment Method (tape, holes, studs), and 8) A sketch or vector file of your design layout. The more detailed your specifications, the more accurate the quote and the final product will be.