In the demanding arenas of industrial machinery, aerospace, defence, and beyond, clear, durable identification isn't just helpful – it's critical. Industrial nameplates serve as the unwavering source of vital information: product names, equipment specifications, safety warnings, and operational data. They provide unmatched visibility and longevity where temporary labels would falter. While plastic has its place for specific indoor or non-conductive needs, aluminium name plate manufacturers stand at the forefront of delivering solutions prized for their exceptional strength-to-weight ratio, corrosion resistance, and versatility. Choosing the right aluminium name plate manufacturers transcends a simple purchase; it's about forging a long-term partnership essential for safety, regulatory compliance, brand integrity, and operational efficiency. This guide details the 7 essential aspects you must evaluate when sourcing aluminium name plate manufacturers.

1. Material Mastery: The Foundation of Aluminium Name Plates

Superior aluminium name plate manufacturers possess deep-rooted expertise in material science. They understand that not all aluminium is equal and guide clients towards the optimal alloy and temper for each unique application:

Alloy Expertise: Knowledge of common alloys is crucial. This includes understanding 5052-H32 (excellent formability and corrosion resistance), 6061-T6 (higher strength, good machinability), and 3003-H14 (good general-purpose, moderate strength). The best aluminium name plate manufacturers select alloys based on required hardness, machinability, and environmental resilience.

Thickness Versatility: Applications range from thin, flexible foil labels (e.g., 0.005" / 0.13mm) to thick, rigid plates (0.125" / 3.175mm+) for heavy-duty impacts. Reputable aluminium name plate manufacturers offer this spectrum.

Surface & Performance Understanding: How different alloys interact with critical processes like anodizing, painting, or etching directly impacts the final look, feel, and durability. True experts predict these outcomes.

Corrosion Resistance Guidance: Recommending the ideal alloy for harsh environments – whether marine, chemical, or outdoor exposure – prevents premature failure. This proactive advice is a hallmark of leading aluminium name plate manufacturers.

2. Advanced Manufacturing & Finishing Capabilities

The core value proposition of premier aluminium name plate manufacturers lies in their technical prowess and breadth of capabilities:

Precision Marking & Engraving:

Chemical Etching: Ideal for intricate, permanent designs and fine detail.

CNC Routing/Milling: Creates 3D effects, deep engraving, and custom cut-outs.

Laser Engraving: High-speed, precise marking for intricate graphics and text.

Dot Peen Marking: Robust method for serialization and basic data.

Stamping & Embossing: Traditional techniques for raised/recessed lettering and logos, often cost-effective for high volumes.

Durable Printing Solutions:

Screen Printing: Uses tough inks for high opacity and longevity.

Digital Printing: Enables full-color, photographic-quality graphics.

Pad Printing: Effective for multi-color logos or irregular surfaces.

Critical Finishing Processes:

Anodizing (Type II & III): The electrochemical cornerstone for aluminium name plates. Creates a hard, corrosion-resistant layer that can be dyed (black, red, blue, gold, etc.) or left clear. Hardcoat (Type III) offers extreme abrasion resistance. Proper sealing is vital. Leading aluminium name plate manufacturers often offer up to twelve anodized colours.

Painting & Powder Coating: Provides specific colours, textures, and enhanced environmental protection.

Brushing/Polishing: Delivers desired aesthetic textures like satin or mirror finishes.

Laminating: Adds protective polyester/polycarbonate films over printed surfaces for superior scratch and chemical resistance.

Rigorous Quality Control: Utilising calibrated equipment for dimensional checks, adhesion testing (tape tests), colour verification, and durability assessments (like salt spray testing) ensures consistent output from trustworthy aluminium name plate manufacturers.

3. Customization Excellence & Design Partnership

Off-the-shelf solutions rarely suffice. Top-tier aluminium name plate manufacturers excel in bespoke solutions and collaborative design:

Design Engineering Support: Translating client concepts (sketches, ideas, specs) into manufacturable, optimized designs. They advise on legibility, size constraints, material suitability, and attachment methods.

Artwork Management: Proficiency in handling diverse file formats (AI, EPS, PDF, TIFF, PSD), cleaning up artwork, optimizing for production, or creating it from scratch.

Rapid Prototyping: Providing physical samples quickly for design verification, material feel, and colour matching before full production – invaluable for complex projects.

Complex Geometries: Capability to produce plates beyond simple rectangles – custom shapes, curves, cut-outs, multi-level engraving, and formed (bent) plates.

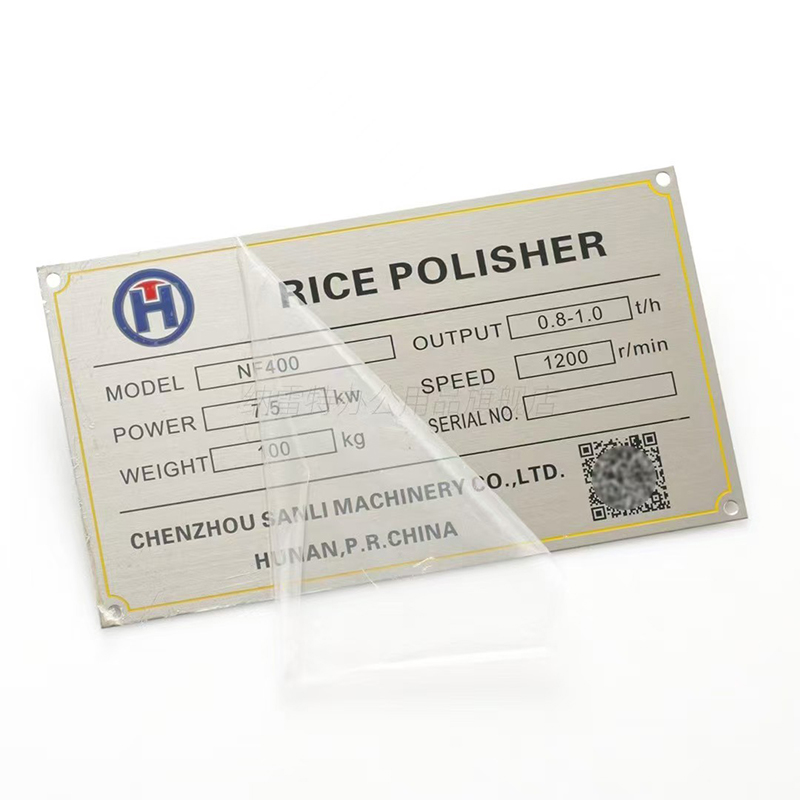

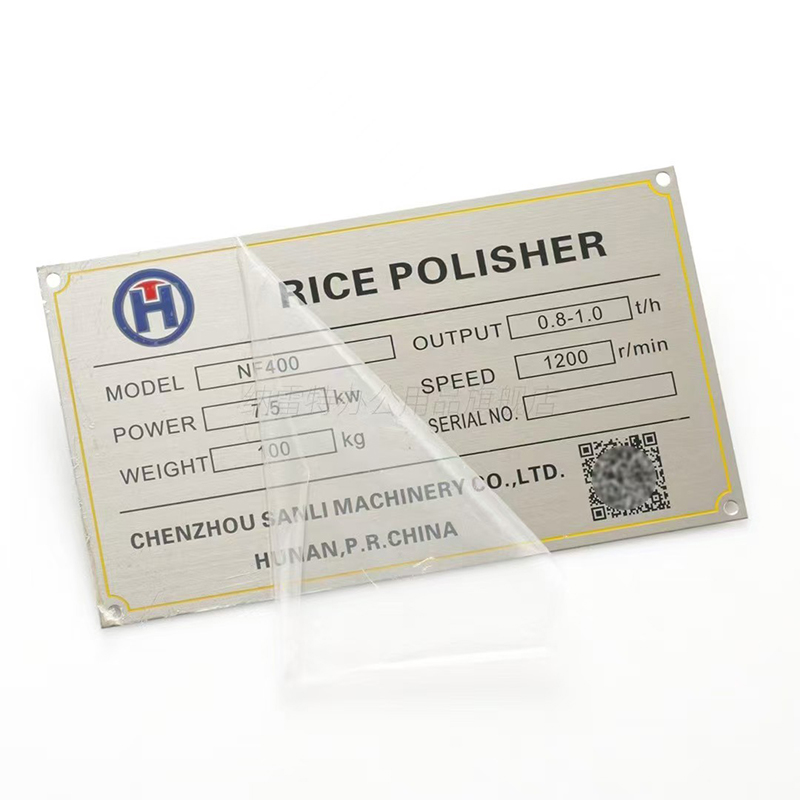

Variable Data Handling: Efficiently managing unique serial numbers, barcodes (1D/2D/QR), UID codes, or sequential data across production runs. Options include engraving, printing, or subsurface printing (sealing graphics beneath the anodized layer for added durability).

Attachment Options: Supplying plates with holes, industrial-grade adhesive backing (like VHB tape), or both, ready for installation.

4. Industry-Specific Knowledge & Compliance Acumen

The best aluminium name plate manufacturers deeply understand the unique, often stringent, demands of various sectors:

Military & Defence: Strict adherence to MIL-STD-130 (UID marking), AS9100 quality systems, and traceability. Expertise in high-strength alloys and finishes for critical data plates near lethal equipment.

Aerospace: Compliance with AS9100, understanding aircraft placard requirements for safety and identification. Expertise in alloys and finishes meeting rigorous performance standards.

Automotive & Transportation: Knowledge of VIN plates, engine tags, component labels, and resistance to fluids, heat, vibration. Meeting OEM specs and regional regulations.

Heavy Machinery & Industrial Equipment: Producing ultra-durable data plates, rating plates, and safety labels resistant to oil, coolant, UV, and abrasion. Understanding UL/CSA requirements.

Electrical Industry: Providing non-conductive options (like phenolic) where needed, or conductive aluminium plates with appropriate markings for identification and safety.

Medical Devices: Biocompatibility (ISO 10993), cleanroom protocols (if needed), FDA traceability, and resistance to sterilization processes.

Marine & Offshore: Mastery of alloys and finishes (e.g., heavy anodizing) for extreme saltwater corrosion resistance.

Experienced aluminium name plate manufacturers proactively navigate these complex regulatory landscapes.

5. Uncompromising Quality Management & Certifications

Consistent quality is non-negotiable. Assess a manufacturer's commitment through their systems:

Certifications: ISO 9001:2015 is the baseline. Industry-specific certs like AS9100 (Aerospace), IATF 16949 (Automotive), or ISO 13485 (Medical Devices) are strong indicators of specialized capability and discipline.

Robust Process Control: Documented procedures, work instructions, and validated processes for key stages (etching, anodizing, printing).

Rigorous Inspection & Testing: Using calibrated tools (calipers, micrometers, colourimeters, adhesion testers, salt spray chambers) and providing detailed reports.

Full Traceability: Systems tracking material batches, production lots, and processes applied to each order – essential for recalls and audits.

Culture of Continuous Improvement: Evidence of proactive efforts to reduce errors and enhance efficiency.

6. Commitment to Sustainability & Environmental Responsibility

Increasingly, businesses prioritize eco-conscious partners. Evaluate aluminium name plate manufacturers on:

Material Sourcing: Use of recycled aluminium content and responsible sourcing policies.

Waste Reduction: Lean manufacturing principles to minimize scrap. Recycling programs for aluminium off-cuts, chemicals (where feasible), and packaging.

Process Efficiency: Energy-efficient machinery, water conservation (especially in anodizing/etching), closed-loop systems.

Responsible Chemical Management: Safe handling, use, disposal, and recycling of process chemicals. Adoption of greener alternatives where viable.

Environmental Certifications: ISO 14001 certification demonstrates a formal commitment to environmental management.

7. Service Excellence & Value-Added Logistics

The partnership extends beyond the initial order. Consider the full service offering:

Responsive Communication: Timely, clear, detailed quoting and a dedicated point of contact.

Accessible Technical Expertise: Willingness to discuss challenges, materials, and design optimizations proactively.

Scalability & Reliability: Handling both low-volume prototypes and high-volume production efficiently with realistic, dependable lead times.

Inventory Solutions: Offering VMI (Vendor Managed Inventory) or Kanban programs to reduce client stockholding costs and ensure JIT delivery.

Secure Packaging & Labelling: Ensuring plates arrive undamaged and are easily identifiable.

Attachment Expertise: Advising on and supplying the best method (adhesives, rivets, screws, welding) for the application surface and environment.

Choosing Your Ideal Aluminium Name Plate Manufacturer Partner

Selecting among aluminium name plate manufacturers requires careful evaluation beyond just price. The ideal partner blends technical mastery, rigorous quality systems, design flexibility, deep industry knowledge, and a commitment to service and sustainability. To make an informed decision:

Request Detailed Samples: Evaluate specific processes, finishes, and material feels firsthand.

Conduct Facility Visits (If Critical): Gain insights into capabilities, organization, and quality culture.

Check Industry References: Speak to clients with similar application demands.

Evaluate Partnership Potential: Look for a manufacturer invested in understanding your long-term needs and growth.

By meticulously vetting aluminium name plate manufacturers against these seven critical criteria, you secure far more than a supplier. You gain a strategic partner dedicated to enhancing your product identification, ensuring safety compliance, elevating your brand image, and driving operational success through the enduring performance of superior aluminium name plates. The right aluminium name plate manufacturers transform raw metal into vital, lasting communication assets for the world's most demanding industries.