Alright, let's talk about marking stuff. Whether you're slapping a nameplate on a million-dollar machine in a Detroit factory, tagging critical components on an offshore oil rig, or just trying to keep your warehouse organized, you need identification that lasts and works. You've got options – plastic labels, adhesive stickers, screen-printed tags, etched metal – but Embossed Metal Tags stand out for some seriously good reasons. Forget the fluff; here are the three fundamental, practical differences that make Embossed Metal Tags the go-to choice when durability, longevity, and reliability aren't just nice-to-haves, they're non-negotiable.

Difference #1: Built Tough vs. Built to Fade (The Durability & Longevity Gap)

This is the big one, the hill Embossed Metal Tags will literally die on (and it takes a LOT to kill them). Let's break down why they laugh in the face of conditions that destroy other tags:

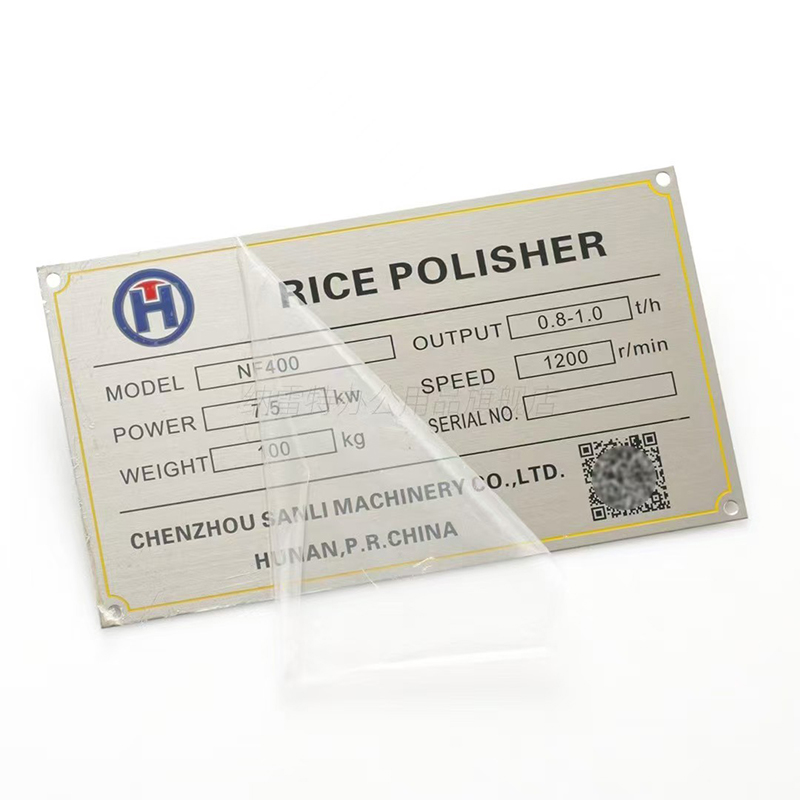

- The Embossing Process = Permanent Marking: When you emboss metal, you're physically deforming it. You're raising the lettering, numbers, or logos out of the solid metal sheet (like aluminum, stainless steel, or brass). This isn't ink sitting on the surface; it is the surface. Compare this to:Adhesive Labels/Stickers: UV rays bleach the ink. Chemicals dissolve the adhesive or the label material itself. Moisture gets under the edges. Abrasion? Forget it. They peel, curl, and become unreadable messes. Fine for a temporary box label, disastrous for permanent asset ID.Screen-Printed/Inkjet Labels (even on metal or plastic): The ink is the weak link. It fades in sunlight, scratches off easily, and can be obliterated by solvents, oils, or just constant handling. That barcode you need to scan? Gone after a few months near machinery.Etched Metal Tags: While durable, the etched recesses can fill up with paint, grease, grime, or corrosion products over time, especially in harsh environments, making the information harder to read. Embossed Metal Tags, with their raised characters, naturally shed debris and stay legible.

- Material Matters (and Embossing Loves Tough Stuff): Embossed Metal Tags are almost exclusively made from metals chosen for their resilience:Aluminum: Lightweight, corrosion-resistant, great for most industrial uses. Embossed characters are clear and durable.Stainless Steel: The king of toughness. Resists corrosion, extreme temperatures, chemicals, and heavy abrasion. Perfect for food processing, chemical plants, marine environments, or anywhere hygiene or harshness is a factor.Brass: Offers excellent corrosion resistance (especially saltwater) and a distinctive, professional appearance. Often used for nautical applications or prestige equipment.

- Weathering the Storm (and Sun, and Chemicals): Think about where tags live:Outdoors: Constant UV exposure? Embossed Metal Tags don't fade. Rain, snow, ice? No problem; the metal and the raised characters endure. Temperature swings from Arizona desert heat to Minnesota winters? Metal handles it far better than plastic, which can become brittle or warp.Industrial Interiors: Oils, greases, solvents, acids, alkalis, cleaning agents? Quality Embossed Metal Tags (especially stainless) resist chemical attack that strips ink or degrades plastics. High-pressure washdowns? They come out clean, not peeling.Physical Abuse: Forklift bumps, tool scrapes, general wear and tear? The raised characters on Embossed Metal Tags can take significant abrasion before becoming illegible. A plastic tag cracks; a sticker shreds.

Pro Tip: If your tags are exposed to anything harsher than an air-conditioned office, the durability gap makes Embossed Metal Tags a long-term cost saver. You're not constantly replacing faded, damaged, or unreadable labels.

Difference #2: Readability You Can Feel (The Tactile & Visual Advantage)

Legibility isn't just about the ink staying put. It's about how easily the human eye (and sometimes hand!) can decipher the information, instantly, in less-than-ideal conditions.

- The Power of Raised Characters: This is the signature feature of Embossed Metal Tags. The text stands proud of the tag surface. Why does this win?Shadow Effect: Light naturally catches the edges of the raised letters, creating shadows that dramatically enhance contrast against the tag background. This makes them incredibly easy to read, even in low light, from awkward angles, or when the tag is dirty. Flat printing offers no such inherent contrast boost.Tactile Confirmation: You can literally feel the information with your fingers. This is invaluable for:Maintenance technicians wearing thick gloves in dark or cramped spaces.Ensuring critical warnings or instructions are identifiable by touch.Compliance situations where positive identification without relying solely on sight is required.Resists Paint Overspray and Grime Buildup: While paint or grime might coat the tag, the raised profile of the characters means the information often remains discernible. You can frequently wipe the grime off the tops of the letters, restoring readability. Flat printed or etched info gets buried.

- Versatility in Finishing: Embossed Metal Tags can be finished in numerous ways to further enhance readability or meet specific needs:Painted: The entire tag is painted, then the raised characters are lightly sanded ("polished") to reveal the bright metal underneath, creating superb high-contrast. Or, the recessed background can be filled with paint ("filled embossed").Anodized (Aluminum): Creates a hard, corrosion-resistant, colored surface. Embossed characters remain the base metal color, providing contrast.Natural Metal: Often used for stainless steel or brass, relying on the natural sheen and shadow of the embossing for readability. Looks sleek and professional.

- Long-Distance Legibility: The combination of size, raised profile, and high contrast makes information on Embossed Metal Tags easier to read from a distance compared to flat-printed alternatives of the same size.

Think About It: When seconds count, or a mistake could be costly (or dangerous), can you afford to squint at a faded sticker or try to decipher grime-filled etching? The tactile and visual clarity of Embossed Metal Tags provides instant, unambiguous information.

Difference #3: Professionalism & Permanence (The Perception Factor)

This difference might seem less tangible, but it's incredibly real, especially for customer-facing equipment, high-value assets, or safety-critical applications. Embossed Metal Tags project quality and permanence.

- The Weight of Quality: Literally and figuratively! A solid metal tag feels substantial. It conveys that the item it's attached to is important, well-made, and built to last. It doesn't feel like an afterthought. Compare picking up a flimsy plastic label versus a sturdy stainless steel Embossed Metal Tag. The message is clear: one is disposable, the other is permanent.

- Unmistakable Permanence: The very nature of embossed metal screams "This information is vital and meant to be here forever." It signals that the manufacturer or owner invested in proper identification. This builds trust with customers and operators. It assures inspectors and auditors that critical data (serial numbers, ratings, warnings) won't vanish.

- Brand Image Enhancement: On finished products, control panels, or premium equipment, Embossed Metal Tags look professional and high-end. They can be customized with logos, borders, and specific finishes to match corporate branding, elevating the overall perception of the product. A cheap sticker or flimsy plastic label cheapens the look.

- Security & Tamper Evidence: While not inherently "tamper-proof," Embossed Metal Tags are much harder to remove cleanly than an adhesive label. Attempting to remove one usually results in obvious damage or bending, providing evidence of tampering. Riveting or welding them on makes removal even more difficult. This is crucial for security seals, calibration tags, or warranty labels.

- Surviving Refurbishment: Equipment often gets repainted or refinished during its lifecycle. Adhesive labels get destroyed. Screen printing gets painted over. Embossed Metal Tags can typically withstand the process; their raised characters ensure the information remains visible even after a new coat of paint is applied (as long as it's not excessively thick over the characters).

The Takeaway: Using Embossed Metal Tags isn't just about identifying an asset; it's about making a statement about the quality, importance, and longevity of that asset. It tells the world, "This matters."

So, When Do Other Options Maybe Make Sense?

Let's be fair. Embossed Metal Tags are often the premium choice, and sometimes alternatives suffice:

- Extremely Short-Term Use: If you literally only need identification for days or weeks (like internal tracking during a specific manufacturing step), a cheap adhesive label might be tolerable.

- Ultra-Low-Cost, Non-Critical Items: For disposable items or things with no safety/environmental/financial consequence if the tag fails, cheaper options exist.

- Highly Complex Graphics/Images: While logos can be embossed, extremely intricate, full-color, or photographic images are better suited to printing processes (though durability suffers).

- Extreme Flexibility Required: If the tag must bend or flex significantly during use (like on a cable or hose), thin plastic labels or specialized flexible tags might be necessary over rigid metal.

The Bottom Line: Why Embossed Metal Tags Win Where it Counts

Choosing an identification method isn't just about the upfront cost per tag. It's about Total Cost of Ownership and Risk Mitigation over the entire lifespan of the asset or product. Embossed Metal Tags shine because they address the core challenges of industrial and commercial identification:

- They Last: They withstand environments that destroy other tags, eliminating the hidden costs and headaches of constant replacement and the risks of missing information.

- They Stay Legible: Through dirt, grime, paint, wear, and poor lighting, the raised characters provide unparalleled visual and tactile readability when you need it most.

- They Command Respect: They project quality, permanence, and professionalism, enhancing brand image and building trust in the integrity of the information they carry.

Embossed Metal Tags are the workhorse, the reliable sentinel of critical information. When failure isn't an option, when information must persist through whatever you throw at it, the differences outlined here make Embossed Metal Tags not just another option, but the definitive solution for durable, reliable, and professional identification. Don't just tag it; emboss it for life.