Let’s be real: you’re probably using some kind of asset tags or labels right now. Maybe they’re plastic, vinyl, or even aluminum. They seem fine… until they fade, peel, crack, or vanish after six months in the field. Suddenly, that "low-cost" solution costs you hours in lost productivity, safety risks, or rework. If this sounds familiar, stainless steel tags might be your operation’s unsung hero. Here’s why making the switch could be your smartest move this quarter.

Why Your Current Tags Are Failing You (And Costing Money)

Think about where your tags live:

- Scorching factory floors melting plastic into goo

- Freezing warehouses making vinyl brittle as glass

- Chemical washdowns dissolving ink like sugar

- Outdoor equipment battling UV rays and acid rain

Standard tags simply aren’t built for this abuse. When labels fail, you get:

Misidentified assets ("Is this Pump A-7 or A-1?")

Safety hazards (faded safety warnings = OSHA violations)

Inventory nightmares (ghost assets haunting your spreadsheets)

Constant replacement cycles (that "cheap" tag? Now it’s $200 in labor to re-tag)

This isn’t just annoying – it’s bleeding cash. Which brings us to the heavy-duty solution…

Stainless Steel Tags: The Unbreakable Workhorse

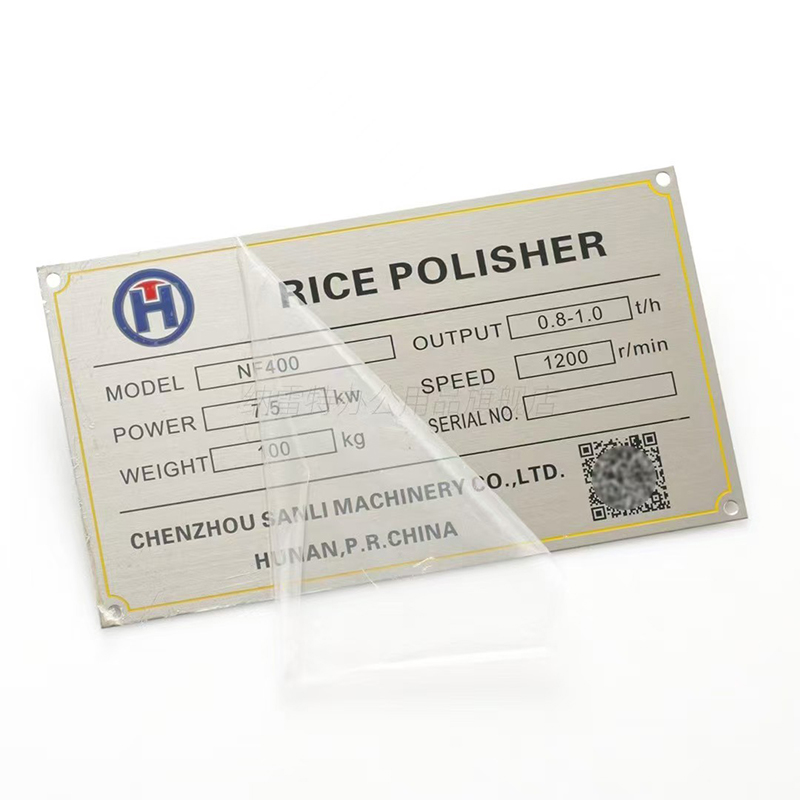

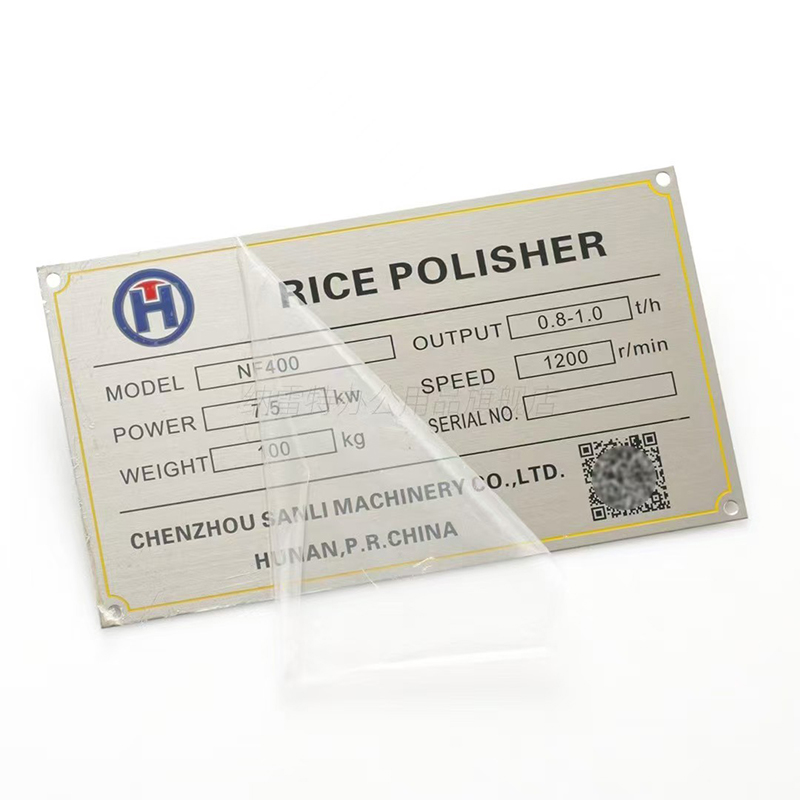

Stainless steel tags aren’t your grandpa’s metal labels. They’re engineered for survival where others quit. Here’s what makes them different:

- Laughs at CorrosionSalt spray? Coolant mist? Fertilizer runoff? Bring it on. 304 and 316L stainless steel tags contain chromium, forming an invisible shield against rust. Perfect for food processing plants, marine environments, or anywhere moisture lives.

- Heat Warrior (No Melting Here)While plastic tags warp at 150°F (65°C), stainless steel tags shrug off temps up to 1,500°F (815°C). Foundry equipment, engine components, exhaust systems – no sweat.

- Chemical Resistance That ImpressesAcids, solvents, oils, cleaners? Stainless steel won’t etch, discolor, or degrade. Critical for labs, pharmaceutical setups, or any place using harsh sanitizers.

- UV? What UV?Direct sunlight for 10 years? Zero fading. Laser-etched or dot-peen markings on stainless steel tags are permanent. No more reapplying labels on solar farm gear or outdoor machinery.

- Vandal-Proof & Tamper-EvidentTry scratching one off. Go ahead. These tags need power tools for removal. Plus, specialty fasteners (like security rivets) make tampering obvious – huge for high-theft areas or regulated assets.

“But aren’t they expensive?”Let’s bust this myth: Yes, stainless steel tags cost more per unit than plastic. But calculate:How often do you replace faded/damaged tags?What’s the labor cost for re-tagging?What’s the risk cost of misidentified critical assets?Stainless steel tags often deliver ROI in under 18 months. They’re a capital investment, not a consumable.

Real-World Wins: Where Stainless Steel Tags Shine

Still skeptical? These industries made the jump and won’t go back:

- Oil & Gas: Offshore rigs using stainless steel tags on valves and pipelines withstand saltwater storms for 15+ years. No more “mystery pipes.”

- Aerospace: FAA-compliant part tracking with ultra-durable tags surviving jet fuel, de-icers, and extreme pressure cycles.

- Wastewater Treatment: Tags readable through sludge, chlorine, and humidity that’d eat aluminum alive.

- Agriculture: Tractor and implement IDs that survive fertilizer dust, mud, and power washing season after season.

- Manufacturing: Asset tags on robotic arms enduring coolant spray and metal shavings daily without failing.

Choosing Your Stainless Steel Tag: Not All Steel is Equal

Ready to upgrade? Know your specs:

| Feature | 304 SS Tags | 316/L SS Tags |

|---|

| Best For | Most industrial environments | Extreme corrosion (marine, chemical) |

| Corrosion Res. | Excellent | Superior (added molybdenum) |

| Cost | $$ | $$$ |

| Marking | Laser etch, dot peen, screen print | Deep engraving for harsh abrasion settings |

Pro Tips:

- Thickness Matters: 0.020" is standard. Need impact resistance? Go 0.032" or 0.063".

- Marking Method: Laser etching is crisp and fast. Dot peening survives paint/powder coating.

- Attachment: Welded tabs? Rivets? Heavy-duty adhesive backs? Match it to your surface.

The Upgrade Checklist: Is It YOUR Time for Stainless?

Answer these questions:

Do your current tags fail within 2 years?

Are you in a wet, hot, corrosive, or outdoor environment?

Is asset misidentification causing safety issues or downtime?

Are you constantly re-tagging equipment?

Do you manage high-value or regulated assets?

If you checked 2+ boxes: Sticking with flimsy tags is costing you more than upgrading. Stainless steel tags are your endgame solution.

Making the Switch: Smart & Scalable

Swapping all tags overnight isn’t realistic. Do this instead:

- Pilot Program: Tag your most abused assets first (outdoor machinery, washdown areas). Track failure rates vs. old tags.

- Phased Rollout: Prioritize critical/safety-related assets (electrical panels, hazardous material lines).

- Standardize: Work with your supplier to create a durable ID system (barcodes, QR codes, human-readable text) that works everywhere.

Bottom Line: Stop Paying the "Cheap Tag Tax"

Stainless steel tags aren’t just durable – they’re profit protectors. They eliminate hidden costs of:

- Re-tagging labor

- Production downtime from misidentified equipment

- Safety fines and liability risks

- Premature asset write-offs

The Upgrade Verdict:

If your operation faces heat, chemicals, weather, or just needs IDs that last as long as the asset – yes, it’s absolutely time to upgrade to stainless steel tags. They’re the last tag you’ll ever buy for that machine.

"Still clinging to plastic tags? That’s like using duct tape to fix a leaky pipe – it might hold for now, but the blowout is coming. Stainless steel is the permanent fix."– Jake R., Plant Maintenance Manager (Switched to SS tags in 2018)

Ready to end the tag-replace cycle? Audit your toughest ID challenges now. Those stainless steel tags will outlive your next three equipment upgrades – and pay for themselves while doing it.