In today’s industrial environments, safety is a top priority. One critical tool that ensures workplace safety is the industrial safety label. These labels communicate hazards, instructions, and warnings to prevent accidents and comply with regulations. Whether in manufacturing, construction, or logistics, industrial safety labels play a vital role in protecting workers and assets.

This article dives into the world of industrial safety labels. We’ll explore their importance, types, and practical uses. You’ll learn how to select, apply, and source these labels effectively. We’ll also cover costs, technology, and common questions. By the end, you’ll have a clear understanding of why industrial safety labels are indispensable for any industrial setting.

Let’s start with the basics.

What Are Industrial Safety Labels?

Industrial safety labels are specialized signs or tags used in workplaces to convey safety information. They are designed to alert people to potential dangers. These labels often include text, symbols, and colors for quick recognition.

They are made from durable materials to withstand harsh conditions. Think of high temperatures, chemicals, or outdoor exposure. The goal is to ensure the message remains visible over time.

Regulations like OSHA in the U.S. or ISO standards globally mandate their use. Non-compliance can lead to fines or accidents. Thus, using proper industrial safety labels is not just a choice but a necessity.

These labels cover various hazards. Examples include electrical shocks, chemical spills, or moving machinery. By providing clear warnings, they help reduce workplace incidents.

In short, an industrial safety label is a key component of safety protocols. It bridges the gap between rules and real-world application.

Different Types of Industrial Safety Labels Compared

Industrial safety labels come in many forms. Understanding the differences helps in choosing the right one. Here’s a comparison of common types.

First, we have hazard warning labels. These indicate specific dangers like “High Voltage” or “Flammable Material.” They often use standardized symbols and colors, such as yellow for caution.

Next, instructional labels provide directions for safe operations. For instance, “Lockout Before Servicing” on machinery. These are crucial for procedures that prevent accidents.

Then, there are certification labels. They show compliance with safety standards. Examples include UL listing or CE marks. These assure that equipment meets regulatory requirements.

Another type is the pipe marking label. Used in facilities with complex piping systems, they identify contents and flow direction. This prevents missteps during maintenance.

Durability varies too. Some industrial safety labels are vinyl-based for indoor use. Others are polyester or aluminum for outdoor or harsh environments. Choosing the wrong material can lead to label failure.

Size and adhesion also matter. Larger labels are more visible but may not fit small equipment. Strong adhesives ensure labels stay put, even in dirty or wet areas.

By comparing these aspects, you can select industrial safety labels that match your needs. Always assess the workplace risks first.

How to Choose and Apply Industrial Safety Labels

Selecting the right industrial safety label involves several factors. Start by identifying the hazard. Is it chemical, electrical, or mechanical? This determines the label’s message and design.

Consider the environment. Will the label face extreme weather, UV light, or chemicals? Opt for materials like polyimide or anodized aluminum for durability. For indoor settings, vinyl might suffice.

Visibility is key. Use high-contrast colors and clear fonts. Symbols should be universally understood. This ensures quick comprehension, even from a distance.

Regulatory compliance is non-negotiable. Check local and international standards. For example, ANSI Z535 in the U.S. specifies label formats. Adhering to these avoids legal issues.

When applying industrial safety labels, surface preparation is crucial. Clean the area to remove dust, oil, or grease. This helps the adhesive bond properly.

Apply labels at eye level or near the hazard point. Avoid placing them on moving parts where they might wear off. Regular inspections are necessary to ensure labels remain intact and legible.

In summary, choose based on hazard, environment, and rules. Apply with care to maximize effectiveness. Proper use of industrial safety labels enhances overall safety culture.

Finding Reliable Suppliers for Industrial Safety Labels

Sourcing industrial safety labels requires finding trustworthy suppliers. Start by searching online for manufacturers or distributors. Use terms like “industrial safety label supplier” or “custom safety labels.”

Look for suppliers with experience in your industry. They should understand specific hazards and regulations. Check their product range—do they offer various materials and sizes?

Certifications are a good indicator of quality. Suppliers with ISO 9001 or similar accreditations often provide consistent products. Ask for samples to test durability and print quality.

Customization options are important. Many workplaces need unique messages or branding. Ensure the supplier can tailor industrial safety labels to your specifications.

Consider lead times and shipping. In urgent cases, quick turnaround matters. Read reviews or ask for references to gauge reliability.

Pricing should be transparent. Avoid hidden costs. Compare quotes from multiple suppliers, but don’t compromise on quality for cheap prices.

Building a long-term relationship with a supplier can benefit both parties. They may offer discounts or better support. Remember, reliable industrial safety labels depend on a reliable source.

Cost Factors for Industrial Safety Labels

The cost of industrial safety labels varies widely. Understanding the factors helps in budgeting. Material choice is a major driver. Vinyl labels are affordable, while metal or specialty materials cost more.

Quantity plays a role. Bulk orders often reduce per-unit prices. However, overordering can lead to waste if needs change.

Customization increases costs. Unique designs, colors, or shapes require extra setup. Standard labels are cheaper but may not fit all scenarios.

Printing technology affects price. Digital printing is cost-effective for small runs. Screen printing or engraving might be pricier but offer durability.

Adhesive type also matters. High-performance adhesives for tough environments add to the expense. Consider the total cost of ownership—cheap labels that fail quickly are not economical.

Regulatory compliance can involve testing or certification fees. These should be factored in. Investing in quality industrial safety labels saves money by preventing accidents and fines.

Plan your budget based on needs. Assess risks and prioritize critical areas. Sometimes, spending more upfront on durable industrial safety labels pays off in the long run.

Technology and Production of Industrial Safety Labels

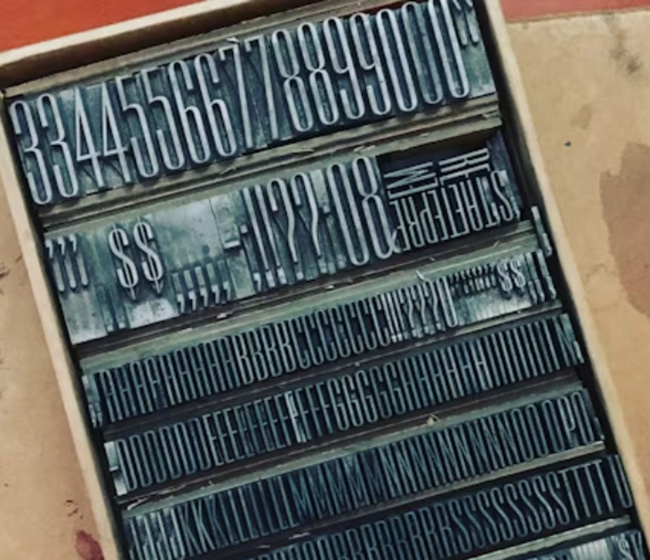

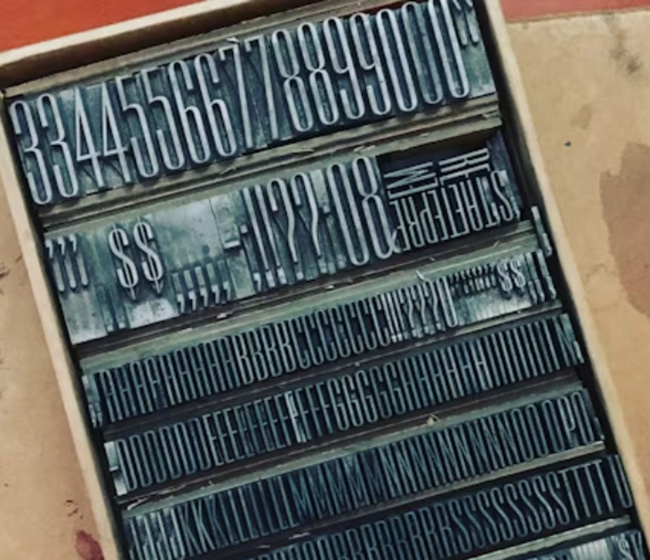

The manufacturing of industrial safety labels involves advanced technology. It starts with design software. Programs like CAD or graphic tools create precise layouts. Symbols and text must meet standards.

Printing methods vary. Digital printing is common for short runs and complex graphics. It allows quick changes and color accuracy. For high-volume orders, flexographic printing is efficient.

Materials are engineered for performance. Polyester labels resist chemicals and abrasion. Aluminum labels withstand high temperatures. Each material undergoes testing to ensure longevity.

Adhesives are formulated for specific surfaces. Acrylic adhesives offer strong bonds in diverse conditions. Silicone-based options work well in extreme heat.

Laminates protect the print from fading or scratching. UV-resistant coatings are used for outdoor labels. These technologies ensure industrial safety labels remain effective over time.

Quality control is strict. Labels are checked for color consistency, adhesion, and durability. Compliance with standards like ANSI or ISO is verified.

Innovations continue. Smart labels with RFID or QR codes are emerging. They provide additional data for safety management. However, traditional industrial safety labels remain essential for basic hazard communication.

Understanding these processes helps appreciate the value of a well-made industrial safety label. It’s not just a sticker—it’s a product of careful engineering.

Frequently Asked Questions (FAQ)

Q1: What are the main purposes of industrial safety labels?

A1: Industrial safety labels serve to warn of hazards, provide safety instructions, and ensure regulatory compliance. They help prevent accidents by communicating risks clearly in workplaces like factories or construction sites.

Q2: How often should industrial safety labels be replaced?

A2: Replace industrial safety labels when they become faded, damaged, or illegible. Regular inspections—at least annually—are recommended. In harsh environments, more frequent checks may be necessary.

Q3: Can I create custom industrial safety labels?

A3: Yes, many suppliers offer customization. You can tailor messages, colors, and materials to specific needs. Ensure custom designs still comply with safety standards to avoid confusion.

Q4: What materials are best for outdoor industrial safety labels?

A4: For outdoor use, choose durable materials like polyester, aluminum, or polycarbonate. These resist UV rays, moisture, and temperature changes. Strong adhesives are also crucial for longevity.

Q5: Are there international standards for industrial safety labels?

A5: Yes, common standards include ISO 3864 for symbols and ANSI Z535 for labeling in the U.S. Always check local regulations, as requirements may vary by region or industry.