If you need an asset label that simply won't quit, you've likely heard about laser engraving. This method creates some of the most durable and reliable identifiers available.

But what exactly are laser engraved labels, and are they the right fit for your project? This article cuts through the noise. We’ll look at how they work, where they excel, and how they stack up against other common labeling methods.

What Are Laser Engraved Labels?

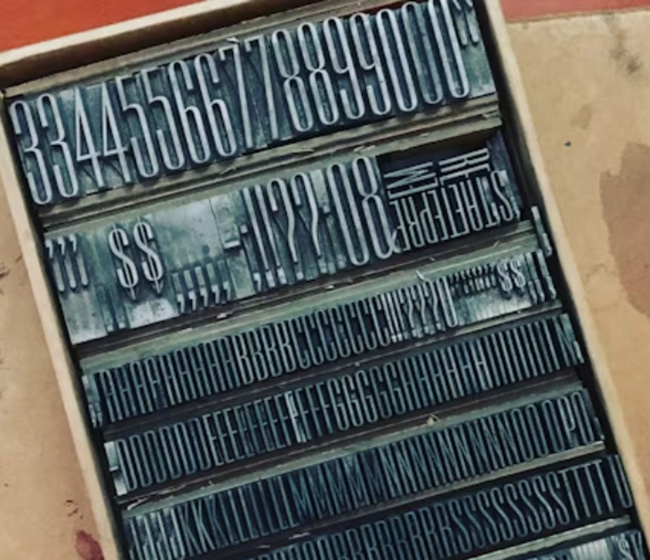

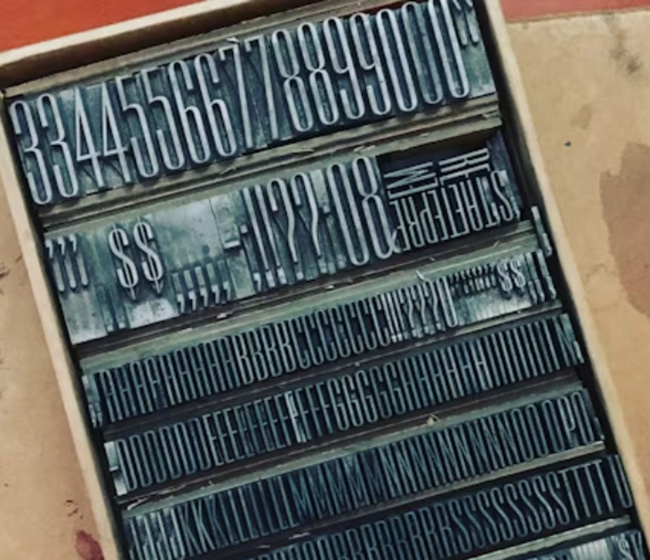

Laser engraved labels are made by using a concentrated beam of light to remove material from the surface of a tag. This process permanently etches text, barcodes, logos, or serial numbers into the substrate.

Unlike printed labels where ink sits on top, laser engraving alters the material itself. This creates a mark that is part of the label, not just on it. The result is exceptional resistance to abrasion, chemicals, and weather.

These are not flimsy stickers. They are typically made from rigid materials like anodized aluminum, stainless steel, or industrial plastics. They are the go-to solution for permanent asset identification.

Laser Engraved vs. Printed Labels: A Clear Comparison

Choosing between engraved and printed labels comes down to durability and environment.

Traditional printed labels use inkjet, thermal transfer, or screen printing. They are cost-effective for indoor, short-to-medium term use. However, the ink can fade, smear, or be scratched off. Solvents and UV light are their enemies.

Laser engraved metal labels, in contrast, offer a different league of performance. The mark will not peel, fade, or rub away. They withstand extreme temperatures, direct sunlight, exposure to oils and fuels, and constant handling.

Think of it this way: a printed label is like using a permanent marker on a tool. A laser engraved label is like stamping your name directly into the metal. One is a coating, the other is a permanent alteration.

Where Laser Engraved Labels Shine: Key Applications

These labels are built for challenging conditions. Their robustness makes them ideal for several critical areas.

- Industrial and Manufacturing: For tagging heavy machinery, tooling, molds, and equipment that sees grease, coolant, and physical abuse. Industrial asset tags need to survive here.

- Aerospace and Defense: Components require permanent identification that meets strict traceability standards and survives harsh operational environments.

- Outdoor and Utility Assets: Electrical panels, pipeline markers, telecommunications gear, and solar farm equipment. These weatherproof labels resist years of sun, rain, and temperature swings.

- Medical and Laboratory Devices: Equipment that undergoes frequent sterilization with autoclaves or harsh chemicals needs labels that won’t degrade. Laser engraved nameplates are a common solution.

- IT Data Centers: While less harsh, server racks and network hardware benefit from permanent engraved tags that won't smudge during handling and last the hardware's lifetime.

Choosing the Right Material for Your Engraved Label

The material you choose directly impacts the label’s look, performance, and cost.

- Anodized Aluminum: The most popular choice. The laser burns through the colored top layer, revealing the bright silver aluminum beneath. This creates a high-contrast, easy-to-read mark. It’s lightweight, corrosion-resistant, and very cost-effective for durable asset tags.

- Stainless Steel: The premium option for the toughest environments. It offers superior resistance to corrosion, high heat, and abrasion. Laser engraved stainless steel tags are common in marine, chemical, and food processing applications.

- Industrial Plastics (like Polycarbonate or ABS): Used when electrical insulation or a specific color is needed. The laser can create a dark, crisp mark on certain plastics. Durability is good but generally less than metal.

- Laminated Metallic Tags: These have a thin metal layer (like aluminum) laminated to a plastic or adhesive backing. They offer a metallic look and good engraving contrast at a lower cost than solid metal, but the metal layer can be thinner.

Finding a Supplier: Questions to Ask

Not all engraving services are equal. When sourcing custom laser engraved labels, ask potential suppliers these questions:

- What material thicknesses can you work with?

- Do you offer different finishes (brushed, matte, glossy)?

- What is the minimum line width or barcode detail you can accurately reproduce?

- Can you provide samples on my chosen material?

- What file formats do you require for artwork (vector files are typically best)?

- Do you handle the design, or do I need to provide finished artwork?

A reliable supplier will guide you through material selection and design rules to ensure your laser etched labels are both functional and legible.

Understanding the Cost Factors

Laser engraved labels have a different cost structure than printed labels. The initial setup and tooling cost (for the digital file) is usually low or nonexistent. The main cost drivers are:

- Material: Stainless steel costs more than aluminum. Thicker materials also increase price.

- Size: The physical area of the label directly impacts material cost and engraving time.

- Quantity: While per-unit costs drop with volume, laser engraving is a serial process (one at a time), so very high quantities can take longer than mass-printed options.

- Complexity: A simple serial number is fast. A complex, filled-in logo or high-density 2D barcode takes more laser time, increasing cost.

Consider the total cost of ownership. A slightly more expensive laser engraved metal tag that lasts 15 years is far cheaper than replacing a printed label five times over the same period.

How the Technology Works: A Closer Look

The process is precise and digital. A vector graphic file guides the laser system. The high-powered laser beam focuses on a tiny spot on the material surface, heating it intensely.

For anodized aluminum, the heat vaporizes the colored dye layer. For stainless steel, it typically creates a controlled oxidation mark, often black or dark brown. In plastics, it often foams or carbonizes the surface to create contrast.

This non-contact method means there’s no tool wear, and it allows for incredible detail and repeatability. Modern fiber lasers have made the process faster and more efficient than ever for creating precision engraved labels.

Design and Legibility Best Practices

To get the best results from your laser engraved labels, follow these tips:

- Use Vector Art: Logos and text should be in vector format (like .AI or .EPS). This ensures sharp, clean edges. Raster images (like .JPG) can result in blurry, pixelated engraving.

- Mind the Font Size: Extremely small fonts may not engrave clearly. Your supplier can advise on minimum legible sizes for your chosen material.

- Consider Contrast: The mark needs to be seen. Black on silver (anodized aluminum) is standard. For stainless steel, you often get a dark mark on a metallic background. Test samples are key.

- Simplify When Possible: While intricate designs can be done, clean, bold designs often yield the most durable and readable permanent identification labels.

Frequently Asked Questions (FAQs)

Q1: Are laser engraved labels really permanent?

A1: For all practical purposes, yes. The mark is created by physically altering the surface material. It cannot be peeled off and is highly resistant to fading, abrasion, and chemicals. It will typically last for the functional life of the asset itself, often decades.

Q2: What materials can be laser engraved?

A2: Many rigid materials work well. The most common for labels are anodized aluminum and stainless steel. Various industrial plastics (polycarbonate, ABS, acrylic) and some coated metals also engrave effectively. Paper, vinyl, and standard plastics are not suitable for this process.

Q3: Can laser engraved labels include barcodes or QR codes?

A3: Absolutely. In fact, they are an excellent method for creating permanent, scannable codes. The high precision of laser engraving produces crisp, high-contrast barcodes that remain scannable for years in tough conditions, making them perfect for asset tracking labels.

Q4: How do I attach a laser engraved metal label?

A4: They are typically not adhesive stickers. Common mounting methods include industrial-grade double-sided adhesive tape (VHB tape), rivets, screws, or welding tabs. The choice depends on the surface and the required security level.

Q5: Are there color options for laser engraved labels?

A5: Direct color engraving is limited. The laser typically creates a contrast mark (like black, white, or brown). However, the base material comes in colors. Anodized aluminum, for example, is available in many standard colors (black, red, blue, gold) before engraving. The laser reveals the silver underneath, creating a two-color label.