Proper labels for chemicals are the first line of defense in workplace and product safety. They communicate critical hazard information in seconds. Getting them right is not just good practice—it’s often the law.

This guide breaks down what you need to know about chemical labeling. We will cover the key standards, required elements, and practical tips for creating effective and compliant labels for chemicals.

Understanding Chemical Labeling Regulations

Navigating the rules for chemical labels is crucial. Non-compliance can lead to severe fines and safety risks.

The Global Harmonized System (GHS)

The GHS is an international standard. It creates a consistent framework for classifying and labeling chemicals. This system uses universal pictograms, signal words, and hazard statements.

Its goal is simple. To ensure a chemical manufactured in one country has the same hazard warnings when used in another. For any business, using GHS-compliant labels for hazardous chemicals is now a global expectation.

OSHA's Hazard Communication Standard (HCS)

In the United States, OSHA's HCS aligns with GHS. It mandates that all hazardous chemicals in the workplace must have appropriate labeling.

The standard requires specific information on every container. This includes the product identifier, hazard pictograms, a signal word, hazard statements, and precautionary statements. Suppliers and employers must ensure chemical container labels meet these requirements.

Key Elements of a Compliant Chemical Label

What exactly belongs on a chemical safety label? A compliant label is a careful assembly of several standardized parts.

Product Identifier and Supplier Information

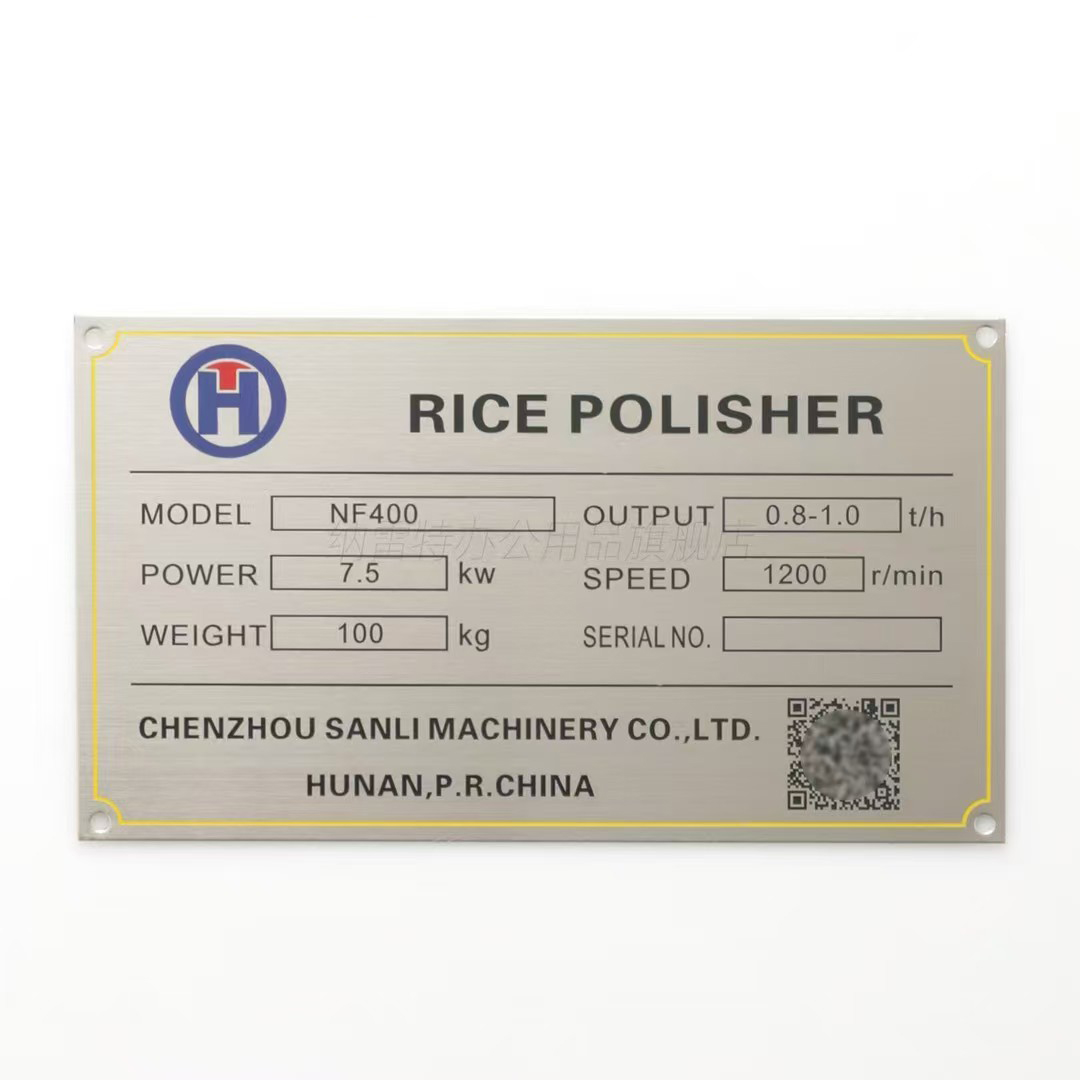

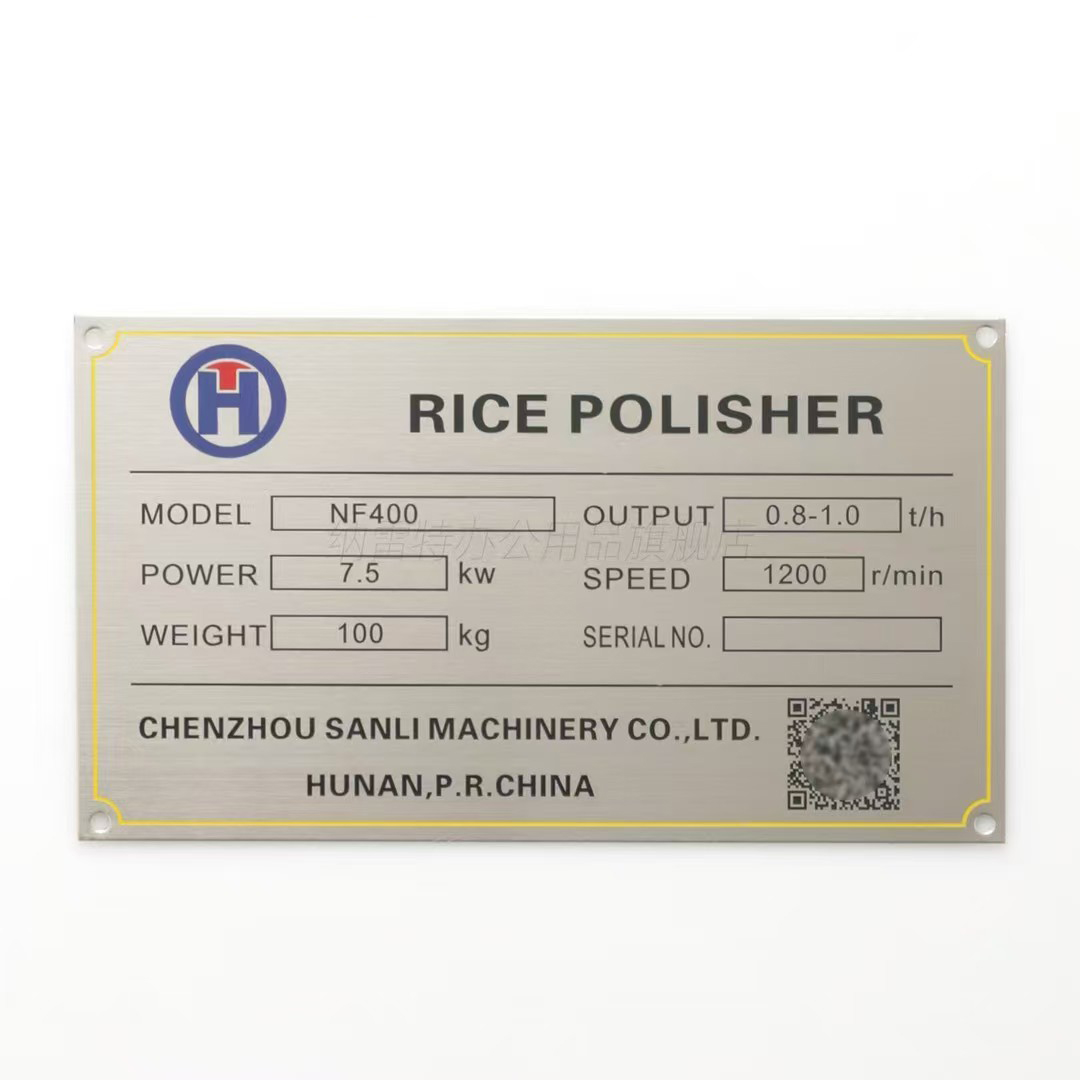

This section clearly states what the chemical is. It can be the chemical name, code number, or batch number. The name and contact details of the manufacturer or supplier must also be present. This allows users to get more information if needed.

Hazard Pictograms

These are diamond-shaped symbols with a red border. Each pictogram represents a distinct type of hazard, like flammability or acute toxicity. There are nine standardized GHS pictograms. They provide an immediate, visual warning to anyone handling the container.

Signal Words and Hazard Statements

"Danger" or "Warning" are the only two signal words used. "Danger" is for more severe hazards. "Warning" is for less severe hazards.

Hazard statements are standardized phrases. They describe the nature and degree of the hazard. Examples include "Causes severe skin burns" or "Highly flammable liquid and vapor."

Precautionary Statements

These statements describe recommended measures. They outline how to minimize or prevent adverse effects from exposure. They cover prevention, response, storage, and disposal. Proper chemical hazard labels must include these practical safety steps.

Types of Chemical Labels and Their Applications

Not all labels for chemicals are the same. The right type depends on the container and its use.

Primary Container Labels

These are the original labels from the chemical manufacturer. They are found on bottles, drums, or cans as purchased. They must contain all GHS/HCS elements. These labels provide the most complete hazard information.

Secondary Container Labels

When a chemical is transferred to another container, like a spray bottle or beaker, it needs a secondary label. OSHA requires these workplace labels for chemicals to at least include the product identifier and general hazards.

For clarity and safety, using a standardized secondary label with all GHS elements is a best practice. It prevents confusion and incomplete information.

Custom and In-House Labeling Solutions

Many facilities use pre-printed or software-generated labels. This ensures consistency across all chemical bottles labels in the lab or plant. Durability is key. Labels must withstand the chemical environment, moisture, and handling.

Best Practices for Designing and Using Chemical Labels

Compliance is the minimum. Effective labels are clear, durable, and consistently used.

Ensuring Durability and Legibility

Labels for chemicals must last for the chemical's entire shelf life and use. Use materials resistant to chemicals, moisture, abrasion, and temperature extremes. Print must be smudge-proof and legible. Font size and contrast are critical for quick reading.

Placement and Consistency

Place labels prominently on the container. Never obscure them. Apply them to a clean, dry surface for maximum adhesion. Most importantly, maintain consistency across your entire facility. Everyone should use the same format and system for chemical identification labels.

Training and Communication

Labels are only effective if people understand them. Regular employee training on the GHS system is essential. Staff must know what each pictogram and phrase means. They should know where to find labels for chemical containers and why they must never remove them.

Common Mistakes to Avoid with Chemical Labels

Even with good intentions, errors can happen. Awareness prevents problems.

Using faded, damaged, or unreadable labels is a major risk. Inspect labels regularly and replace them immediately if compromised.

Another common error is incomplete secondary container labeling. A simple name like "Solvent" is not enough. Always include full hazard information.

Do not ignore updated safety data sheets (SDS). If an SDS is revised, the chemical product labels may also need an update to reflect new hazard information.

Finally, never assume everyone knows the hazards. Always rely on the standardized information on the label, not informal knowledge.

The Future of Chemical Labeling

Technology is changing how we manage labels for chemicals. Digital systems and smart labels are on the rise.

Some companies use QR codes on labels. Employees can scan them to access the full SDS instantly on their phone. This provides real-time, detailed information beyond the physical label.

Sustainability is also becoming a focus. The industry is exploring eco-friendly label materials. These must maintain durability while reducing environmental impact.

Regulations will continue to evolve. Staying informed about changes to GHS or OSHA HCS is a permanent part of chemical safety management. Your processes for creating hazard labels for chemicals must be adaptable.

Frequently Asked Questions (FAQs)

Q1: What is the minimum information required on a workplace secondary container label?

A1: OSHA requires at least the product identifier (chemical name) and general hazard information. However, best practice and many company policies demand a full GHS-style label with pictograms, signal word, and precautionary statements to ensure safety and clarity.

Q2: How often should chemical labels be reviewed or replaced?

A2: Labels should be visually inspected regularly. Replace them immediately if they become damaged, faded, or illegible. Furthermore, if the chemical's Safety Data Sheet (SDS) is updated with new hazard information, the corresponding labels for chemicals must be updated promptly.

Q3: Can I use my own company's design for chemical labels, or must they follow a strict template?

A3: You can use a custom design, but it must include all mandatory elements required by the GHS and OSHA HCS. This includes the prescribed pictograms, signal words ("Danger" or "Warning"), and standardized hazard statements. The design should prioritize clarity and readability.

Q4: Are there specific materials recommended for printing durable chemical labels?

A4: Yes. For containers exposed to harsh environments, use synthetic label materials like polyester, polyethylene, or vinyl. These resist moisture, chemicals, and abrasion. Always use industrial-grade printers and inks designed to produce permanent, smudge-resistant images for chemical safety labels.

Q5: Who is responsible for labeling chemicals in a workplace?

A5: Responsibility is shared. The chemical manufacturer or supplier must provide a compliant label on the original primary container. The employer is then responsible for ensuring all chemical containers in the workplace—including secondary containers—are properly labeled according to OSHA's Hazard Communication Standard.